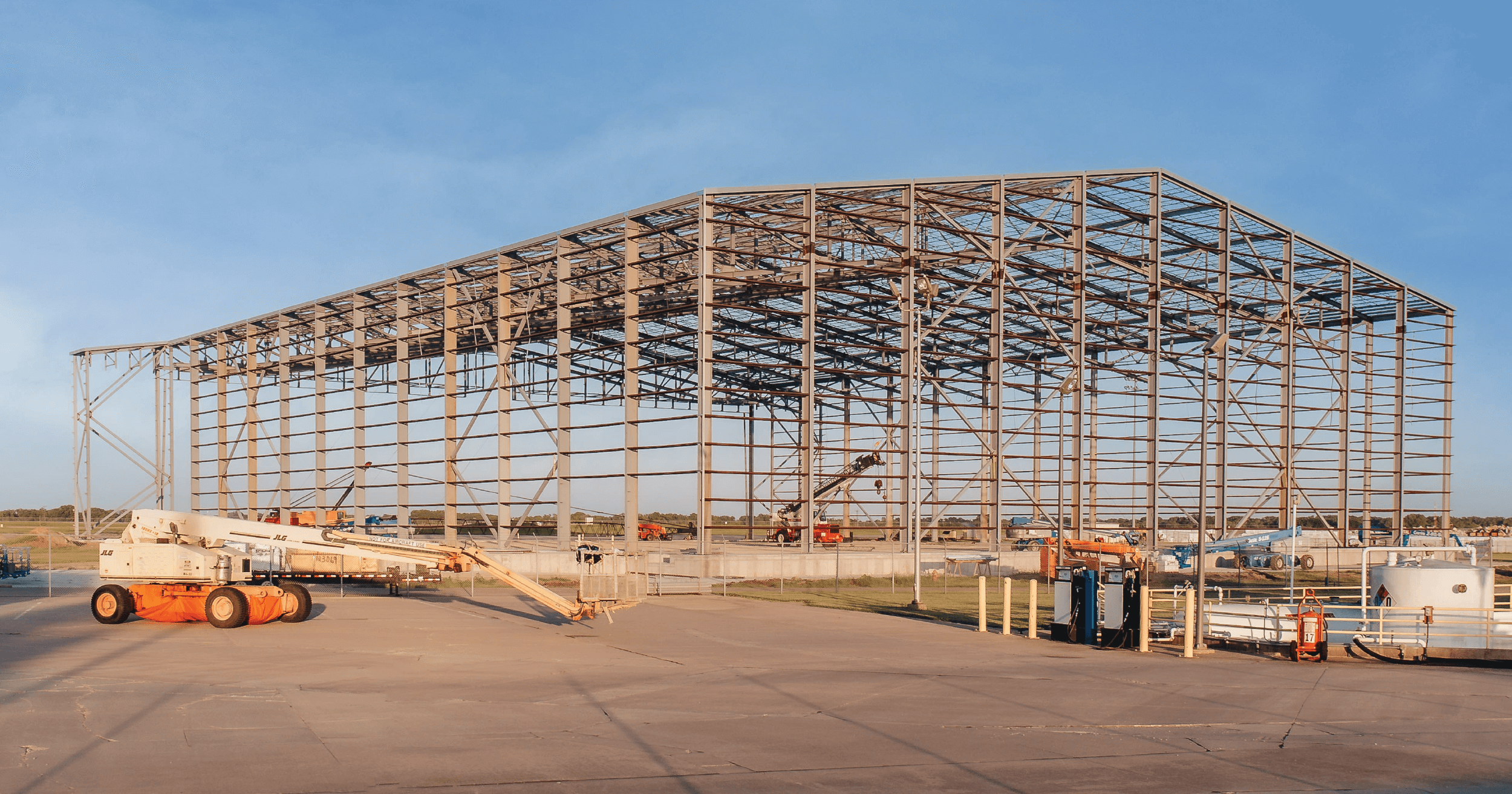

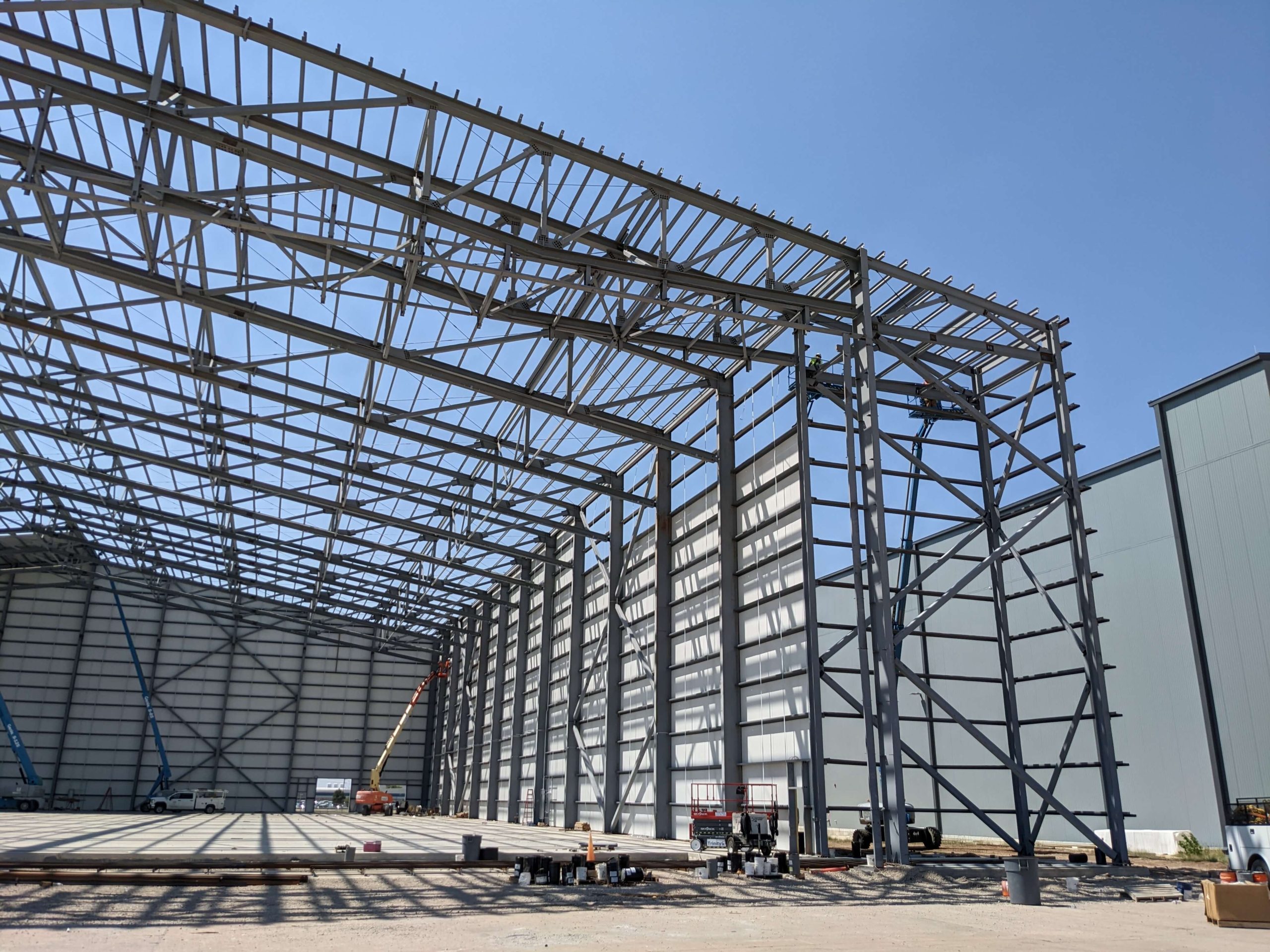

Structural Provides Behind the Scenes Support

June 20, 2024

Did you know elephants walk on their tiptoes? It’s true. While it might seem odd that an animal that can weigh 10,000 pounds or more walks on its tiptoes, the elephant’s unique foot structure is perfect for holding up the massive animal and allowing it to navigate the uneven ground and swampy conditions of its natural habitat.

Elephants are just one example of how important the things you can’t see are in design – whether in nature or in man-made objects. So often, it’s the things that are hidden that make the biggest difference in the stability and soundness of a structure, a fact structural engineers know well.

“One thing I feel like sets structural engineering apart from the other engineering disciplines is our role goes even more behind the scenes,” says Neil Satrom, structural/architectural engineer for MKEC. “We are really just supplementing the building on the backside making sure it’s sturdy and strong, that it doesn’t blow down in the wind or shake too much in an earthquake.”

But just like an elephant’s foot doesn’t operate separately from the rest of its body, structural engineers also don’t work in a vacuum. “We have to be able to work alongside our other disciplines to make sure we provide what they need,” Satrom says. “A lot of times we play a more secondary role because the mechanical needs are really what’s driving the project, we’re just trying to work around what it is that they need.”

Commercial vs. industrial

While the end goal is always the same – create a structure that serves the needs of the stakeholders that is safe and durable – not all structural engineering is the same. Differences abound between the commercial and industrial sides of the discipline.

“On the commercial side, we tend to work for architects for the most part,” Satrom says. “We’ll get hired by an architect who has already met with an owner who has already started to lay out the needs for a building. They have a general idea of what they want the floor plan to look like, and we’ll sit down with them and try to figure out what the best building system is for the type of result that they want.”

Things start a little bit earlier on the industrial side.

“On the industrial side, we’ll get involved a little bit sooner,” says Andre Razo, structural/architectural engineer and principal for MKEC. “We’ll be working hand in hand with our mechanical or electrical team. You don’t just go out and throw up a structure. A lot of times we’re building on top of existing structures and forced to set columns and beams in certain locations that maybe wouldn’t be our first choice. Maybe on the commercial side you have a little more freedom there.”

In addition, the look of the structure isn’t as important on the industrial side of things.

“On the industrial side, aesthetics isn’t really a concern,” Razo says. “It’s function over form. We do what we have to do to support the piping, cable tray, or whatever we’re putting up in a pipe rack or on a vessel. Everything is unique. A lot of our details are very repetitious, but it takes a lot of effort to figure all that out.”

Despite the differences, one thing holds true for both sides of the discipline. “You’re just trying to work with the space that you have,” Satrom says. “On the industrial side, you’re trying to fit columns in between existing stuff. On the commercial side of things, I’m trying to figure out how I can hide this structure, so you don’t impede the space. Our greatest goal is that someone walks into a building and doesn’t notice the structure at all.”

Plenty of variety

The structural engineering group at MKEC never lacks for interesting projects, and that’s one of the things that Satrom likes the most.

“I enjoy being able to work on everything from massive facilities that are hundreds of thousands of square feet to some really random problems that come up that you need to figure out on some old building someplace,” he says. “We have projects that have fees that are $1,000, and we have fees that are several hundred thousand and anything in between.”

“I enjoy being able to work on everything from massive facilities that are hundreds of thousands of square feet to some really random problems on some old building someplace.”

Neil Satrom, Structural/Architectural Engineer

That variety makes structural engineering an easy job to love.

“The thing that I love about my job the most is I get to come in and figure out some fairly complex situations,” Razo says. “We’re working through a lot of situations that are very unique. I just like all the different things we get to do here.”

Contributing to that variety and MKEC’s success with customers who need structural engineering services are the nearly 30 structural engineering professionals available to work on projects at MKEC.

“That’s a pretty good size structural group because at least on the commercial side an architect will work on a project and they work on two or three projects at one time, whereas the structural engineers in our office, we can be working on 10 to 15 projects at a time,” Satrom says.

In addition, the structural team works closely with other in-house teams like mechanical and electrical, which benefits MKEC’s clients.

With our team working together, we can meet the goal of creating the best design for our clients. Our structural engineering team puts its best foot forward to design structures that best meet our client’s needs – even if most people never see the work they do.

“We work through complex issues together, and I think our clients get a better design in the end.”

Andre Razo, Structural/Architectural Engineer, Principal